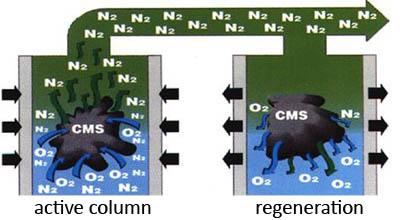

The Nitrogen-Pressure-Swing-Adsorption (PSA)-System consists of two carbon molecular sieves (CMS), each one embedded in an aluminium column.

Pre-treated pressurized air enters the first, “active?? column at the bottom and passes the CMS. Oxygen and other trace gases are preferentially adsorbed at the CMS, as the oxygen molecules fit into the pores of it, whereas the nitrogen passes the sieve.

After a preset time, when the active sieve reaches its capacity, the generator switches from the first to the second column, and the first one enters a regeneration process, while the second one continues the air separation, so that there is a constant flow of pure nitrogen.

The first, saturated CMS is regenerated by a fast reduction of the pressure in the column, so that the absorbed gas is released, so that it can be removed from the column. Afterwards the first column is ready for use, when the second one reaches is capacity.

The constant alternation between the two columns gave the technology the name Pressure-Swing-Adsorption (PSA).

The difference of the CMS to standard activated carbon is its pore size, which allows only oxygen and other trace gases to enter the pores. Bigger molecules, like in our case nitrogen, are excluded from entering the pores. This leads to a separation of the nitrogen from all other gas molecules in the air.

Gas quality: Depending on the request from 98% up to 99.999% (including further purification).

For very high requirements we offer special installations that produce nitrogen with a purity of 99%. Further purification leads to a gas quality of more than 99.999%. The benefits of this procedure are the high possible savings of energy and very small investment costs.